Kunststoff-Spritzguss: modernste Technologie mit Jahrzehnten Erfahrung.

Kunststoff-Spritzguss: Spezialisierung plus.

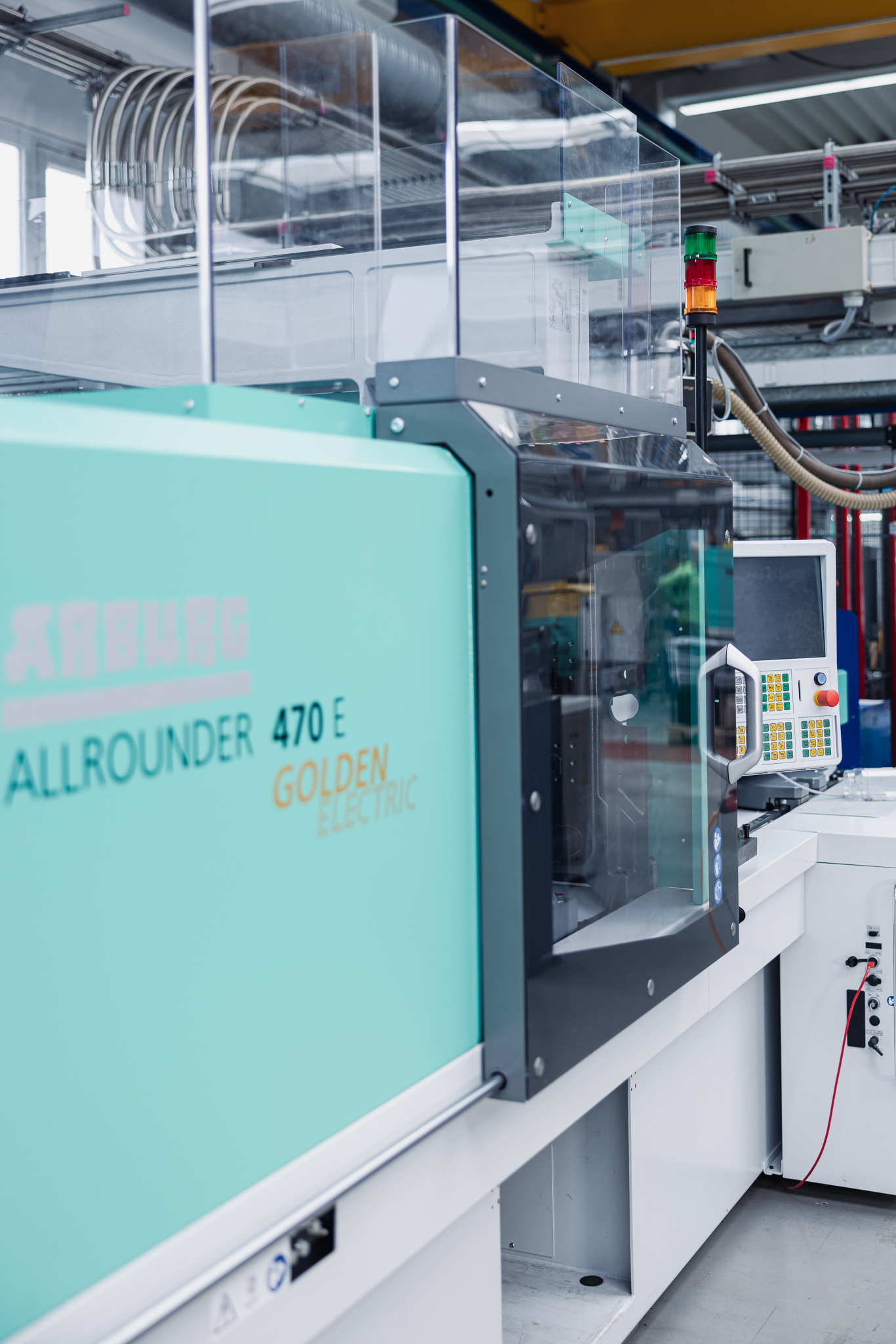

Die KOMOS-Spezialisierung auf die Verarbeitung thermoplastischer Kunststoffe schätzen zahlreiche Anwender in der Automobilindustrie und der Bauindustrie, in der Medizintechnik, der Elektrotechnik, der Elektronik und vielen weiteren Branchen. Dank jahrzehntelanger Erfahrung arbeiten wir und unsere modernsten Maschinen auf qualitativ höchstem Niveau – mit exakt der Präzision, die Sie zu Recht für Ihr Produkt im Kunststoff-Spritzguss erwarten.

Dabei verarbeitet KOMOS für Sie im Kunststoff-Spritzguss alle gängigen thermoplastischen Kunststoffe wie

"PA, ABS, PC, POM, ASA, Blends, PE, PS, PP, PUR und TPE."

Doch KOMOS kann noch mehr als Kunststoff-Spritzguss: In unserem hybriden Technologieverbund aus Kunststoff-Spritzguss, Stanzen/Umformen und CNC-Drehen bieten wir Ihnen eine außergewöhnliche Fertigungsbreite und -tiefe, ergänzt mit zahlreichen weiteren Leistungen, sodass wir gemeinsam mit Ihnen stets die ideale Lösung entwickeln können, damit Ihr Kunststoff-Spritzguss-Produkt exakt Ihre Anforderungen erfüllt.

Kunststoff-Spritzguss mit einzigartigen Lösungen für erfolgreiche Produkte.

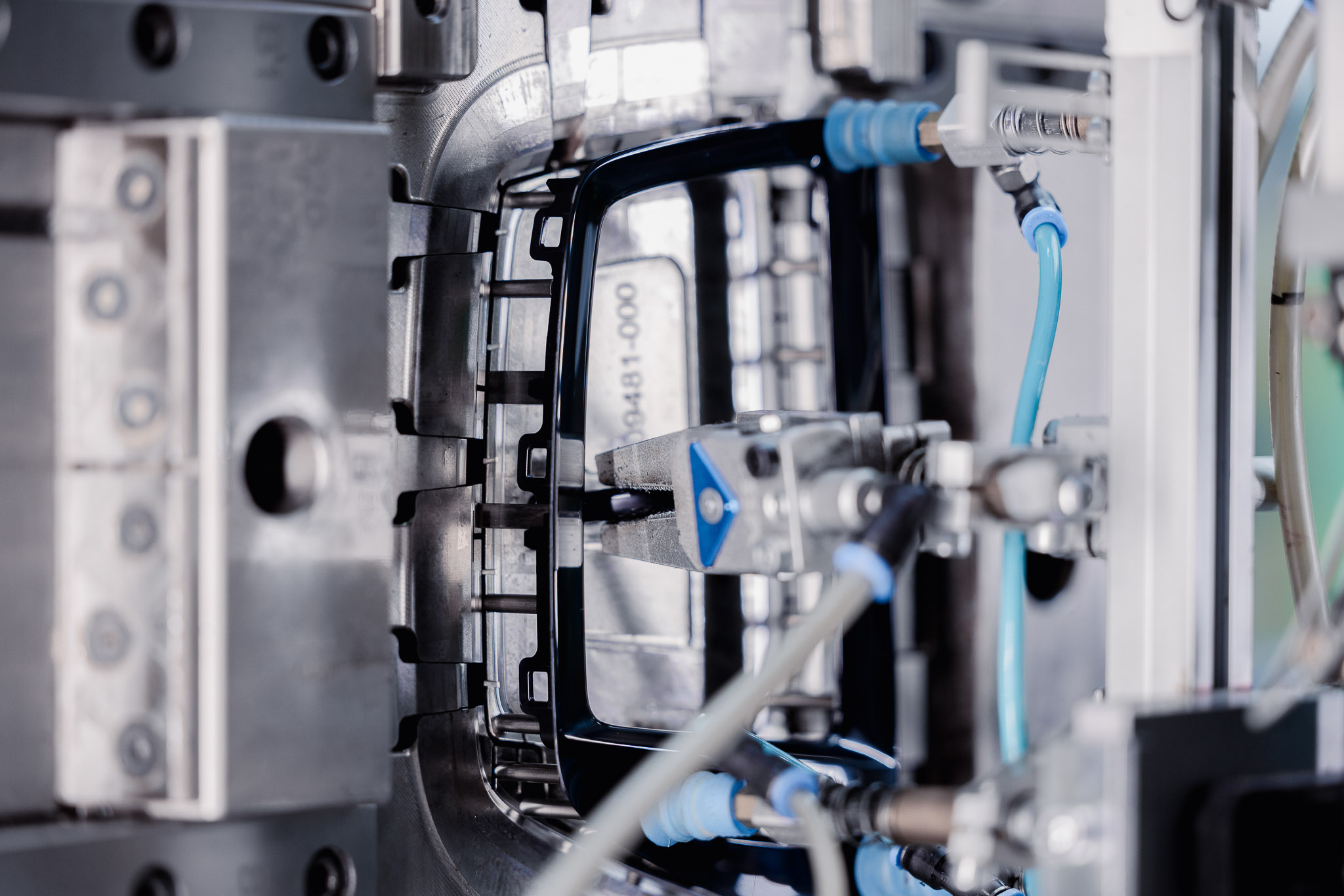

Design und Hochglanz: anspruchsvolle Oberflächen mit Kunststoff-Spritzguss

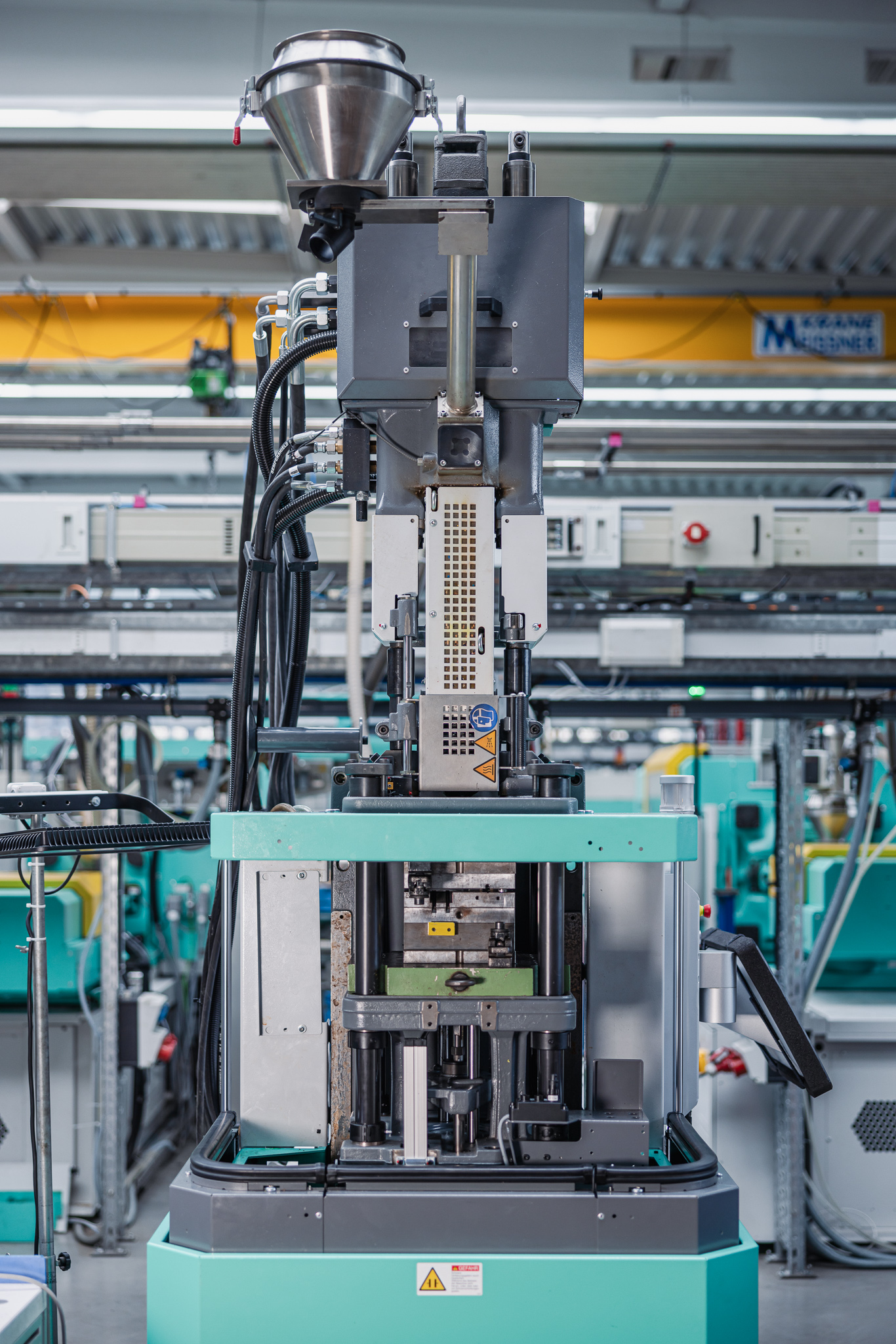

Die modernen Maschinen bei KOMOS ermöglichen die Herstellung von Kunststoff-Spritzguss-Teilen mit einem Gewicht von 2 g bis zu 826 g bei Werkzeugschließkräften von 15t bis 200t. Diese sind mit CNC-Handling-Systemen ausgestattet, sodass wir für Sie anspruchsvolle Design-Oberflächen sowie optische Hochglanzoberflächen herstellen können.

Verchromt und lackiert: hochwertige Oberflächen

Kunststoff-Spritzguss-Teile zum Verchromen bzw. Lackieren sind eine KOMOS-Spezialität. Unsere horizontalen und vertikalen Maschinen im Kunststoff-Spritzguss arbeiten mit einfachen und komplexen Werkzeugen. Diese können mit Heißkanälen, Mehrfachkavitäten und hydraulischen Kernzügen ausgestattet werden.

Manuell oder automatisiert: Montagevorgänge und Verpackung integrierbar

Selbstverständlich können wir bei KOMOS manuelle oder automatisierte Montagevorgänge in den Kunststoff-Spritzguss-Prozess integrieren. Optional können wir Ihre Kunststoff-Spritzguss-Teile sofort nach dem Spritzgießvorgang konfektionieren und vollautomatisch verpacken.

Thermoplastische Elastomere – ideal für Kunststoff-Spritzguss.

Thermoplastische Elastomere (TPE) vereinen wichtige positive Eigenschaften von Gummi und Kunststoff, also der Kunststoffe und der Elastomere, und sind zudem vollständig recyclebar. Sie sind bei Raumtemperatur elastisch, biegsam und flexibel, bieten also gummiähnliche Gebrauchseigenschaften und verschiedene Shore-Härten.

Die physikalische Vernetzung der Elastomere macht eine aufwendige Vulkanisation praktisch überflüssig. Zudem erlauben die Eigenschaften der TPE einen wiederholten Verformungsprozess.

Weitere Verarbeitungsvorteile der thermoplastischen Elastomere im Kunststoff-Spritzguss:

- kurze Zykluszeiten und entsprechend niedrigerer Energieverbrauch

- schweißen und kleben möglich

- einfach einzufärben

- Kombination von harten und weichen TPE-Komponenten mit Mehrkomponententechnik möglich

Thermoplastische Elastomere finden breite Anwendung in Automobilindustrie und Bauindustrie, in Medizintechnik und Elektrotechnik sowie vielen weiteren Branchen. Sie begegnen uns in vielen Industrie-Produkten wie Schuhen, Sportartikeln und anderen Konsumgütern. Weil sie lebensmittelecht und ungiftig sind, eignen sie sich sogar für die Herstellung von Spielzeug.

Soft-Touch-Haptik oder Hochglanz-Optik

Es gibt zahlreiche thermoplastische Elastomere speziell für haptisch ansprechende Dekorflächen mit makelloser Oberflächenqualität, dabei emissions- und geruchsfrei. So sind angenehm weiche, haptische Oberflächen mit komplexen geometrischen Strukturen ebenso möglich wie hochwertig anmutende Hochglanz-Flächen.

Überzeugende Kunststoff-Spritzguss-Lösungen für Ihr Produkt

Die KOMOS-Experten stehen bereit, um Sie und Ihr Unternehmen in Sachen Kunststoff-Spritzguss, Produkt- und Technologieentwicklung zu unterstützen – und freuen sich auf Ihre Herausforderung!

KOMOS verarbeitet für Sie

Kunststoff (PA, ABS, PC, POM, ASA, Blends, PE, PS, PP, PUR, TPE)

Stahl (Automatenstahl, Edelstahl)

NE-Metalle (Messing, Aluminium, Kupfer, Bronze)

Sondermaterialien (Hartpapier, Folien)

© 2023 Komos GmbH | Alle Rechte vorbehalten.

KOMOS im Social Web