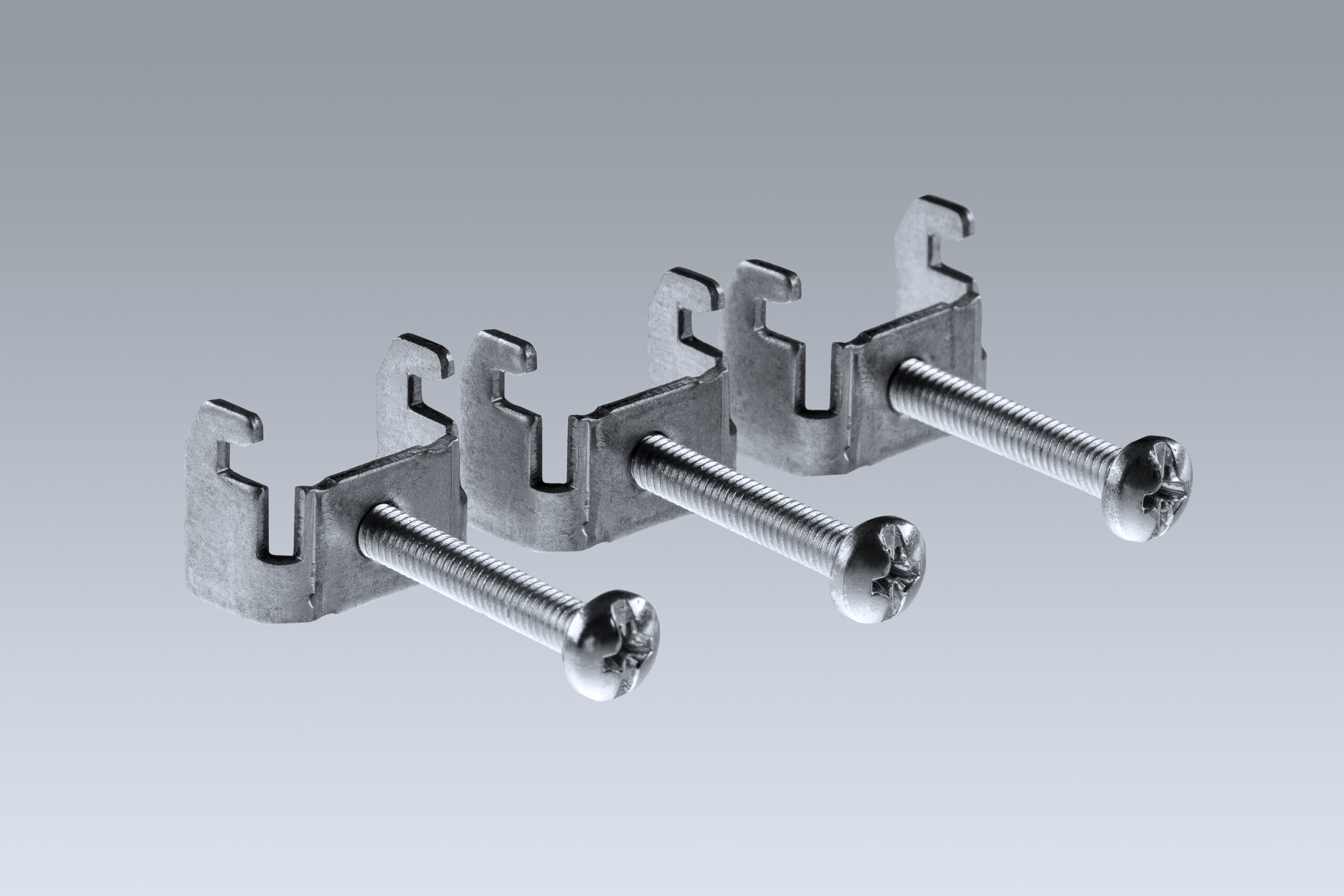

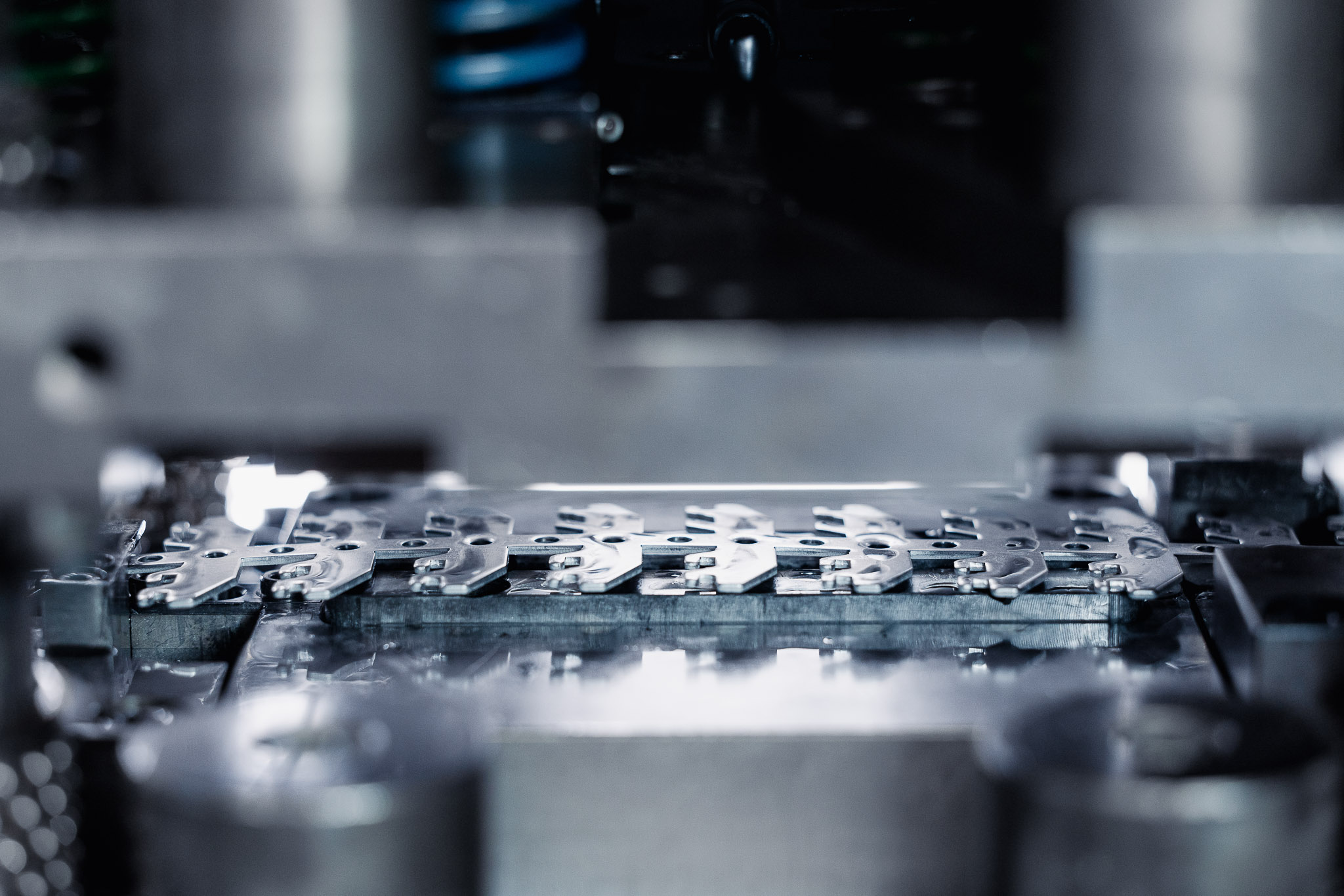

Ausgeprägt hochwertig: Stanzteile in beeindruckender Qualität.

Stanzteile mit Tiefgang. Und mehr.

Von einfach bis hochkomplex, dabei immer in überzeugender und gleichbleibender Qualität: KOMOS verfügt über modernste Maschinen für Stanzen und Tiefziehen, um Ihre Stanzteile exakt und zuverlässig nach Ihren Vorgaben herzustellen – und das stets wirtschaftlich in der gewünschten Stückzahl von Klein- über Mittel- bis Großserie. Und selbstverständlich mit den verschiedensten Möglichkeiten der Oberflächenbehandlung Ihrer Stanzteile.

Oft steht das Stanzteil am Beginn einer Produktionskette und/oder ist nur Teil eines fertigen Produkts. Idealerweise bietet Ihnen KOMOS deshalb in seinem hybriden Technologieverbund aus Stanzen/Umformen, CNC-Drehen und Kunststoff-Spritzguss eine außergewöhnliche Fertigungsbreite und -tiefe, sodass Ihren Vorstellungen und Anforderungen kaum Grenzen gesetzt sind. Dazu kommt ein breites Spektrum weiterer Leistungen wie Montage, Qualitätsprüfung und Verpacken oder auch Forschung & Entwicklung.

Auf Wunsch können wir – über das einzelne Stanzteil hinaus – gemeinsam mit Ihnen die komplette Lösung entwickeln: von Ihrer Idee bis zum fertig angelieferten Produkt

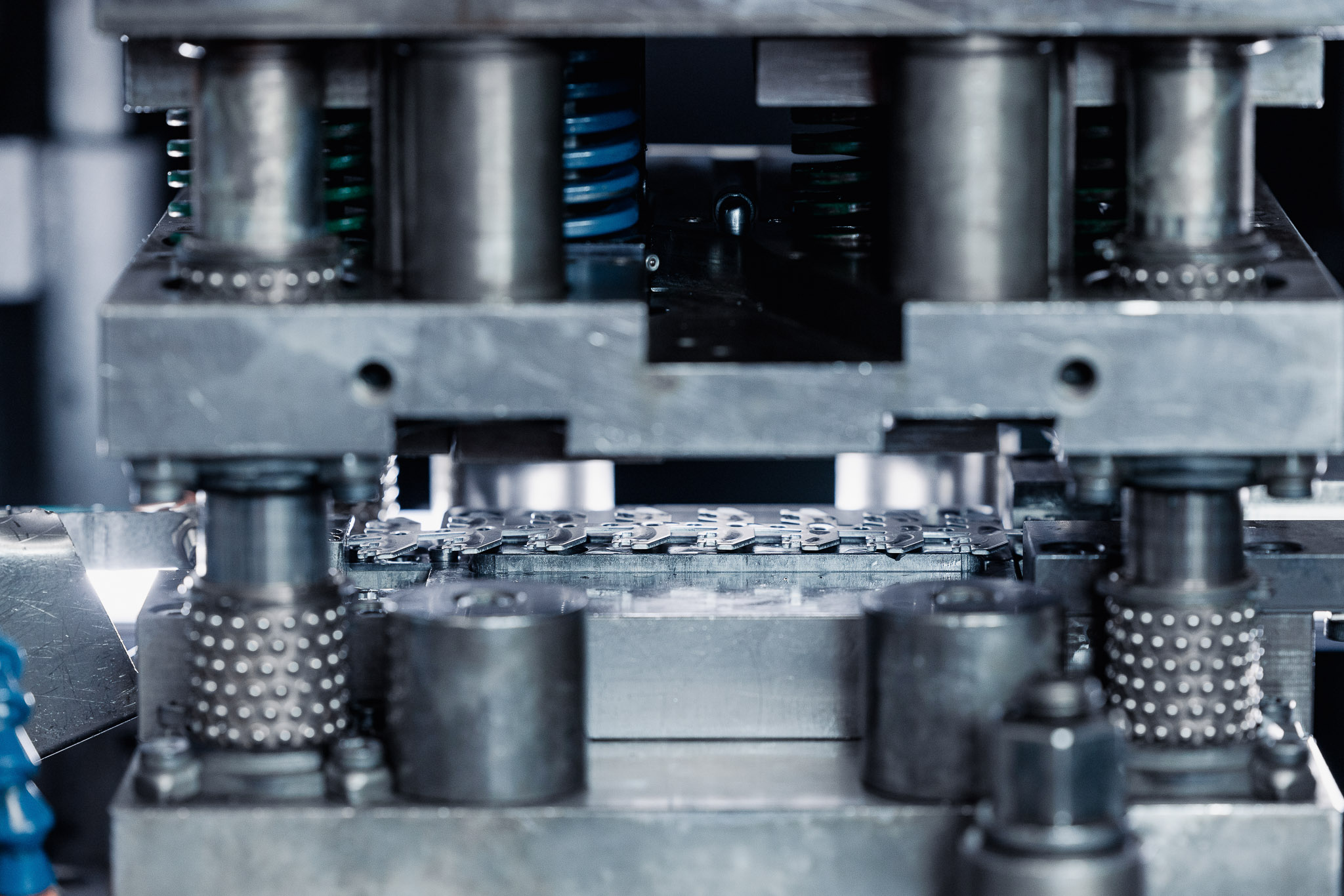

Bis zu 200 Tonnen Druck für Ihr Stanzteil.

Modernste Maschinen für anforderungsgerechte Umform- und Stanzteile

KOMOS verfügt über den Maschinen- und Technologiepark, um Ihre individuellen Wünsche für Ihr Produkt gezielt umzusetzen. Dabei können wir Umform- und Stanzteile aus nahezu jedem Metall fertigen; im Einzelschnitt und auch im Folgeverbund mit einer Presskraft unserer hydraulischen/pneumatischen Stanzen von 3,15T bis 60T und unseren Extenter Stanzanlagen von 40T bis 200T.

Während des Biegens können viele beliebige Formen und Konturen in das Werkstück eingebracht werden. Dabei bleibt das Gewicht erhalten, weil nichts abgetrennt wird.

Beim Stanzen trennt ein Schneidewerkzeug ein oder mehrere Flachteile aus dem Material. Die auszustanzende Form wird gleichzeitig von oben und von unten durch die Schneidkanten des Werkzeugs und der Unterlage (Stempel) abgetrennt.

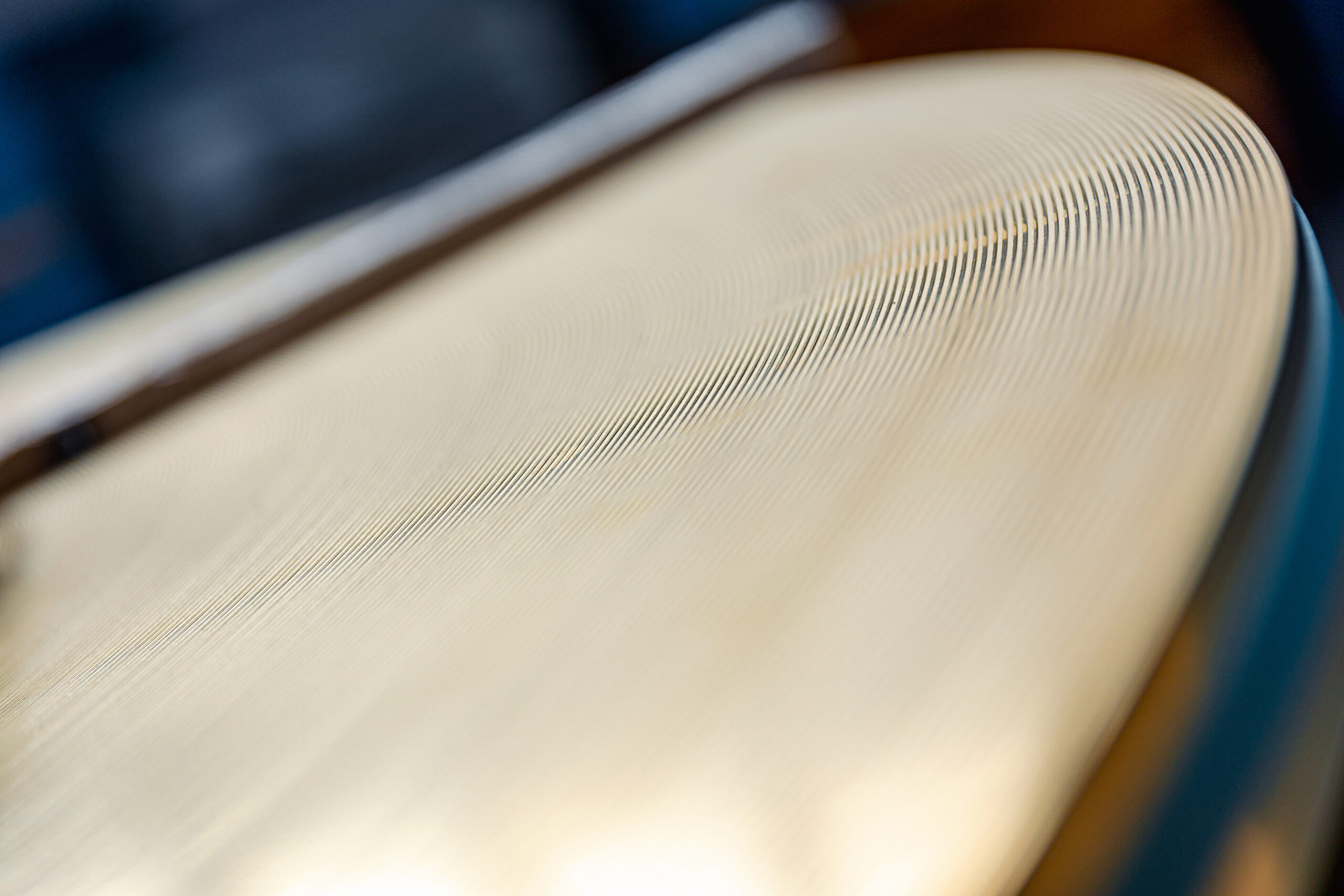

Beim Ziehen wird durch Zugdruck die vorher festgelegte Form des Materials verändert und umgeformt.

Mehr als nur Stanzteile.

Da Stanzteile i. d. R. nur Komponenten von Produkten sind und selbst auch meist erst den Beginn einer Produktionskette bilden, bieten wir bei KOMOS Ihnen ein umfangreiches Spektrum weiterer Leistungen, etwa

- Trowalisieren

- Härten

- Pulverbeschichten

- Lackieren

- Gewindeschneiden

- Oberflächenbearbeitung

- Weiterverarbeitung zu Baugruppen in unserer Montageabteilung

Stanzteile nach Ihren Vorgaben

Die KOMOS-Experten stehen bereit, um Sie und Ihr Unternehmen in Sachen Kunststoff-Spritzguss, Produkt- und Technologieentwicklung zu unterstützen – und freuen sich auf Ihre Herausforderung!

KOMOS verarbeitet für Sie

Kunststoff (PA, ABS, PC, POM, ASA, Blends, PE, PS, PP, PUR, TPE)

Stahl (Automatenstahl, Edelstahl)

NE-Metalle (Messing, Aluminium, Kupfer, Bronze)

Sondermaterialien (Hartpapier, Folien)

© 2023 Komos GmbH | Alle Rechte vorbehalten.

KOMOS im Social Web