Wo Technik auf Vertrauen trifft.

Seit mehr als 30 Jahren.

KOMOS in Bürgel

Familiengeführt. Fortschrittsgetrieben.

Seit 1991 entwickeln und fertigen wir komplexe elektromechanische Baugruppen, die höchsten Ansprüchen genügen – in Präzision, Zuverlässigkeit und Effizienz. Ergänzt wird unser Angebot durch die Herstellung von Kunststoff-Spritzteilen, Dreh- und Stanzteilen, die wir nahtlos zu ganzheitlichen Systemlösungen verbinden.

Technologie. Service. Partnerschaft.

Was bei KOMOS entsteht, kommt aus einer Hand – von der Entwicklung bis zur Endmontage. Mit kurzen Wegen, hohem Automatisierungsgrad und einem Team, das für Qualität brennt.

100 % Made in Germany. 100 % Verantwortung.

Wir hören zu, denken mit – und liefern exakt das, was Ihre Prozesse erfordern.

Vom Prototyp über die Nullserie bis zur Serienproduktion.

Von der Idee bis zur pünktlichen Anlieferung in Ihrem Werk.

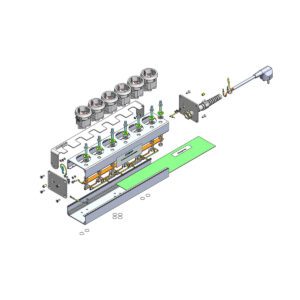

Komponenten - Module- Systeme

Das Angebot von KOMOS für Ihr Unternehmen umfasst hochwertige Komponenten, Module und Systemlösungen – präzise gefertigt, durchdacht montiert und zuverlässig geliefert.

Als Spezialist für Kunststoff-Spritzguss, Drehteile und Stanztechnik kombinieren wir diese Fertigungsverfahren zu leistungsfähigen Produktlösungen. Unsere Komponenten werden montagefertig weiterverarbeitet – vom Fügen, Veredeln und Prüfen bis zur Kommissionierung – exakt abgestimmt auf Ihre Anforderungen.

Modulfertigung bei KOMOS bedeutet mehr als Produktion: Wir beraten Sie ganzheitlich, entwickeln technische Lösungskonzepte und begleiten Ihre Projekte vom ersten Entwurf bis zur Serienreife – mit Blick auf Funktion, Fertigung und Budget.

Als zertifizierter Systemlieferant steht KOMOS für Qualität, Flexibilität und Effizienz. Seit 1997 sind wir nach DIN EN ISO 9001 zertifiziert, seit 2025 nach ISO 13485 für die Medizintechnik und fertigen nach der IATF 16949 (Automobilnorm). Produktfreigaben erfolgen nach VDA oder PPAP.

Branchenkompetenz ist unsere Stärke: Wir liefern maßgeschneiderte Lösungen für Medizintechnik, Automobilindustrie, Elektrotechnik, Maschinenbau, Luft- und Raumfahrt sowie viele weitere Branchen mit hohen Qualitätsanforderungen.

Kunststoff-Spritzguss

KOMOS ist auf die Verarbeitung thermoplastischer Kunststoffe spezialisiert – erfahren Sie mehr über Ihre Möglichkeiten mit unserem innovativen hybriden Technologien-Verbund, auch im Rahmen einer komplexen Produktstrategie.

Drehen

KOMOS schätzt traditionsreiche, beständige und qualitativ zuverlässige Produktionsverfahren – und modernisiert auch das Drehen, digitalisiert und entwickelt es weiter und gestaltet es so noch effizienter.

Stanzen & Umformen

Stanzen und Tiefziehen von einfach bis hochkomplex, in Klein-, Mittel- und Großserie, bei stets gleichbleibender Qualität: Erfahren Sie, was wir und unsere Maschinen zuverlässig und präzise für Sie leisten.

Montage & Verpackung

Rund um seine Fertigungstechnologien bietet Ihnen KOMOS vielfältige Leistungen: Trowalisieren, Härten, Pulverbeschichten, Lackieren, Gewindeschneiden sowie Oberflächenbearbeitung, vor allem jedoch die fachgerechte Montage zum fertigen Endprodukt. Dazu kommen Qualitätsprüfungen jeglicher Art, Verpackung und vieles mehr.

KOMOS: Innovation – Vielfalt – Zukunft

Wir denken voraus, investieren gezielt in neue Technologien und entwickeln uns stetig weiter – organisatorisch, technisch und kulturell. Forschung & Entwicklung, interne Digitalisierung und flexible Fertigungskapazitäten sichern uns und unseren Kunden die notwendige Agilität in einem zunehmend komplexen Umfeld.

Verantwortungsbewusstes Handeln gehört für uns ebenso zur Zukunftssicherheit wie partnerschaftliches Denken: gegenüber Kunden, Mitarbeitenden und Ressourcen.

Steckdosen & Anschluss-Module

Seit über zwei Jahrzehnten entwickelt KOMOS modulare Lösungen für sichere und langlebige Anschluss-Systeme: darunter medizinische Steckdosenleisten und Module für LAN, Telefon und TV. Unser Fokus liegt auf Robustheit, Montagefreundlichkeit und klarer Funktionalität – abgestimmt auf den realen Einsatz.

Verlässlichkeit. Nähe. Made in Germany.

Als Zulieferer aus Bürgel stehen wir für kurze Wege, schnelle Entscheidungen und direkte Kommunikation. Durch unsere regionale Fertigung garantieren wir nicht nur Qualität und Termintreue, sondern ermöglichen auch schnelle Reaktionszeiten – ein echter Vorteil im Tagesgeschäft.

Besondere Anforderungen? Unser Alltag.

Sie haben eine Idee, die nicht ins Standardformat passt? Genau das reizt uns. Mit technischem Know-how, vernetzten Prozessen und einem engagierten Team lösen wir Herausforderungen individuell – von der ersten Skizze bis zur Serienreife.

Zukunft durch Weiterentwicklung

Wir denken voraus, investieren gezielt in neue Technologien und entwickeln uns stetig weiter – organisatorisch, technisch und kulturell. Forschung & Entwicklung, interne Digitalisierung und flexible Fertigungskapazitäten sichern uns und unseren Kunden die notwendige Agilität in einem zunehmend komplexen Umfeld.

KOMOS: Drei Jahrzehnte industrielle Präzision.

Seit über 30 Jahren ist die KOMOS GmbH aus Bürgel verlässlicher Partner für anspruchsvolle Auftragsfertigung. Unternehmen verschiedenster Branchen verlassen sich auf unsere Erfahrung, unsere technische Souveränität und unsere Fähigkeit, auch komplexe Anforderungen pragmatisch umzusetzen.

KOMOS denkt in Lösungen, agiert mit Verantwortung – und bleibt dabei konsequent kundenorientiert. Regional verbunden, national gefragt.

2022 – Digitalisierung, nächster Schritt

Es wird weiter digitalisiert: Werkzeug- sowie Mess- und Prüfmitteltools ebnen den Weg in die Zukunft genauso wie das neue Energiemanagement – Maßnahmen, die sich jeden Tag aufs Neue als optimal erweisen, auch für die Kunden von KOMOS.

2022 – neue Arbeitsumgebung

Das Verwaltungsgebäude wurde saniert und bietet seit dem Bezug Großraumbüro und Mitarbeiterküche, auch um die Kommunikation untereinander und damit Betriebsklima, Kreativität und Effizienz zu stärken.

2021 – KOMOS goes digital

KOMOS startete seine Digitalisierungsoffensive, zusammen mit einem umfassenden Maschineinvestitionsprogramm. So wurden u. a. Leitstand und ein Rechnungsverarbeitungstool eingeführt.

2020 – Generationswechsel II

Anfang 2020 wurde der 2004 begonnene Generationswechsel abgeschlossen: Gründer Manfred Schneider übertrug seine Geschäftsanteile an Antje Blumentritt; seit dem 01. März 2020 wird die KOMOS GmbH in Bürgel durch Antje Blumentritt und Karsten Blumentritt als Geschäftsführer vertreten.

2016 – Zukunft

Nachhaltigkeit ist seit Beginn an ein wichtiger Unternehmenswert. Deshalb wurden bei KOMOS in Bürgel u. a. 2016 ein Energiemanagementsystem implementiert und 2019 die erste Photovoltaikanlage in Betrieb genommen.

2010 – mehr Kapazität II

2010 wurde eine neue zweigeschossige Spritzerei- und Lagerhalle in Bürgel in Betrieb genommen, die ehemalige Spritzereihalle wurde zur Montageabteilung mit neusten Montageautomaten umgebaut. Zu dieser Erweiterung der Produktionskapazitäten gehörten auch Investitionen in neue Verpackungsmaschinen mit Bedruckung sowie Bestückungs-Vollautomaten.

2004 – F&E

Ebenfalls ab 2004 wurde ein eigenständiges F&E-Team aufgebaut. So konnten erste Kundenaufträge als Komplettlösung von Entwicklung bis zu Montage umgesetzt werden. Gleichzeitig entwickelte KOMOS in Bürgel die Produktfamilie Daten- und Netzwerktechnik und verschiedene Produkte für Anwendungen in der Medizin- und Elektrotechnik.

2004 – Generationswechsel I

Constanze Bürger und Karsten Blumentritt erweiterten die Geschäftsführung; KOMOS-Gründer Manfred Schneider übertrug die ersten Geschäftsanteile an seine Töchter Constanze Bürger und Antje Blumentritt – wichtige Schritte für die Weiterführung des Bürgeler Familienunternehmens. 2006 schied Manfred Schneider aus der Geschäftsführung aus.

1999 – Anschluss unter diesem Modul

Etwas Eigenes: Die Chance, Produktion und Vermarktung der Geräteeinbaudose von Busch Jaeger zu übernehmen, war 1999 der Startschuss für den Aufbau des KOMOS-eigenen Produktsortiments Anschluss-Module. 2001 folgten 4- und 6-fach-Steckdosenleiste, bis heute zur medizinischen Steckdosenleiste weiterentwickelt; 2010 kam die modulare Anschlusseinheit in der Kategorie Kat.6A aus Bürgel auf den Markt.

1997 – mehr Kapazität I

Die erste neue Produktionshalle mit neuem Außenlager ging 1997 in Bürgel in Betrieb. Seit Gründung konnte die Kunden- und Technologiebasis deutlich ausgebaut werden, mit Highlights wie Hohlschrauben aus der Dreherei, Fensterhebertastern und Bremssystemen für die Automobilindustrie oder Energiewürfeln für Produktionsanlagen. In dieser Zeit entstand die Basis für das heutige KOMOS-Sortiment der Anschlusskomponenten.

1993/94 – Fenster und Alarm

Nach der Erweiterung des Fertigungsspektrums um einen eigenen Fensterbau wurde bereit 1994 das erste von KOMOS selbst entwickelte Produkt am Markt etabliert: das Modulare Alarmgebersystem.

1991 – Start

Bereits damals wurden Produkte und Baugruppen aus Kunststoff und Metall für die Elektro- und Kommunikationsindustrie hergestellt: Am 1. Oktober 1991 gründete Manfred Schneider die KOMOS GmbH durch den Erwerb des Betriebsteils „Armaturen Bürgel“ von der Tridelta AG mit den Abteilungen „Stanzerei und Automatendreherei“ sowie „Plastspritzbereich mit Montage“ und fast 100 Mitarbeitern.

KOMOS verarbeitet für Sie

Kunststoff (PA, ABS, PC, POM, ASA, Blends, PE, PS, PP, PUR, TPE)

Stahl (Automatenstahl, Edelstahl)

NE-Metalle (Messing, Aluminium, Kupfer, Bronze)

Sondermaterialien (Hartpapier, Folien)

© 2023 Komos GmbH | Alle Rechte vorbehalten.

KOMOS im Social Web