KOMOS | Smart Home – Intelligente Systeme, zuverlässig zur Serie gebracht

Smart-Home-Technologien sind aus modernen Lebensräumen nicht mehr wegzudenken. Doch wirklich intelligente Systeme entstehen erst, wenn Technologie über Design hinausgeht – wenn sie sicher, nachvollziehbar und dauerhaft zuverlässig funktioniert.

Wir entwickeln und realisieren marktfähige Smart-Home-Systeme – integriert, skalierbar und serienreif.

Denn ein smartes System funktioniert nur, wenn jede Komponente ihren Platz kennt. Wir fertigen die, die passen.

How do you benefit from this?

Through lower development risks, faster certification and a product quality that is measurably convincing.

Our philosophy is: right from the start.

This includes risk analyses, simulations and clearly defined test points — for safety before the product goes into series production.

Smart home development that inspires

Smart-Home-Produkte müssen heute schnell marktreif, zuverlässig skalierbar und langfristig stabil sein.

Wir begleiten Sie von der ersten Idee über Entwicklung und Industrialisierung bis zur Serienfertigung – mit klarem Fokus auf Funktion, Nutzererlebnis und Wirtschaftlichkeit.

Areas of application

Unsere Smart-Home-Lösungen kommen überall dort zum Einsatz, wo vernetzte Systeme zuverlässig funktionieren müssen – von Steuerungs- und Sensoreinheiten über Kommunikationsmodule bis hin zu kompletten Geräteplattformen.Typical fields of application:

- Sensors and measurement technology: Assemblies for temperature, motion and humidity measurement

- Communication modules: Radio and control boards for building automation and energy management

- Touch interfaces: Control panels with capacitive or DekTouch surface for light and room control

- Ready-to-install assemblies: Electronics, mechanics and cabling combined into tested complete systems

KOMOS thus covers the entire functional range of modern smart home systems — from individual sensors to complete, networked systems.

Smart Home specialization

Wir entwickeln vernetzte Smart-Home-Systeme mit Fokus auf Serienreife, Skalierbarkeit und stabile Funktion.

Als Systempartner übernehmen wir Verantwortung für Systemintegration, Schnittstellen und die sichere Überführung in die Serie.

Smart Home verstehen wir nicht als Einzelgerät, sondern als vernetztes Gesamtsystem mit Markt- und Nutzerfokus.

Robert Blumentritt

Sales management

Smart home development that inspires

KOMOS accelerates the path from idea to production-ready product — without compromising on quality or safety.

Our interdisciplinary approach reduces interfaces, creates transparency and saves valuable development time.

Your advantages:

Up to 50 % shorter development time, proven by parallel tool and electronics development.

Proven IoT platform as a technical basis — standardized, secure and flexibly expandable.

Reusable modules and tools shorten development cycles and minimize the risk of errors.

Early simulations and prototype tests secure design decisions and avoid rework.

Areas of application

Our technologies are used wherever precise sensors, reliable communication and durable housings are required. Typical fields of application:

- Sensors and measurement technology: Assemblies for temperature, motion and humidity measurement

- Communication modules: Radio and control boards for building automation and energy management

- Touch interfaces: Control panels with capacitive or DekTouch surface for light and room control

- Ready-to-install assemblies: Electronics, mechanics and cabling combined into tested complete systems

KOMOS thus covers the entire functional range of modern smart home systems — from individual sensors to complete, networked systems.

Smart Home specialization

We develop and manufacture smart home products for all leading standards Matter, Thread, Zigbee and WLAN. From design to series production, our development, mechanics and electronics work seamlessly together — for tested, ready-to-install assemblies from a single source. Our focus:

- Certified developments according to Matter and Thread

- Compatible designs for Zigbee, Z‑Ware and WLAN systems

- Cybersecurity by design — Data security integrated right from the start

In the own test laboratory we test every product under realistic conditions:

- EMC test according to IEC 61000–4‑2 / ‑3 / ‑6 (up to ± 8 kV air, ± 4 kV contact, 10 V/m field strength)

- Temperature change tests according to IEC 60068–2‑14 from — 40 °C to + 85 °C

- UV resistance according to ISO 4892–2 over 1 000 h xenon arc exposure

Protection class tests up to IP68 according to DIN EN 60529 (1 m water depth / 60 min)

All measurement results are documented in internal test reports and are traceable. On request, we can provide digital serial or release reports — for quality that is not claimed, but proven.

Robert Blumentritt

Sales management

From the idea to series production — our structured process

A clear process creates security and speed. Our development process is transparent, documented and designed to identify technical risks at an early stage and keep development times predictable.

1. analysis & target definition — 1–2 weeks

We record all technical and economic requirements, define interfaces and jointly determine the quality criteria.

2. concept & simulation — 3–4 weeks

In this phase, we test variants, simulate functions and evaluate material and production options.

Risks are documented and covered by preventive measures.

3. prototyping & testing — 2–4 weeks

We create functional samples and test them for EMC, temperature resistance and mechanical resilience.

Each prototype is documented with a test report and measurement data.

4. series release & production — 6–8 weeks

After successful validation, the series release follows.

Our production includes end-of-line testing, traceability and release documentation in accordance with ISO 9001 and ISO 13485.

5. support & lifecycle management — continuous

Even after the start of series production, we accompany your products throughout their entire life cycle -

from change management and firmware updates to the optimization of existing assemblies.

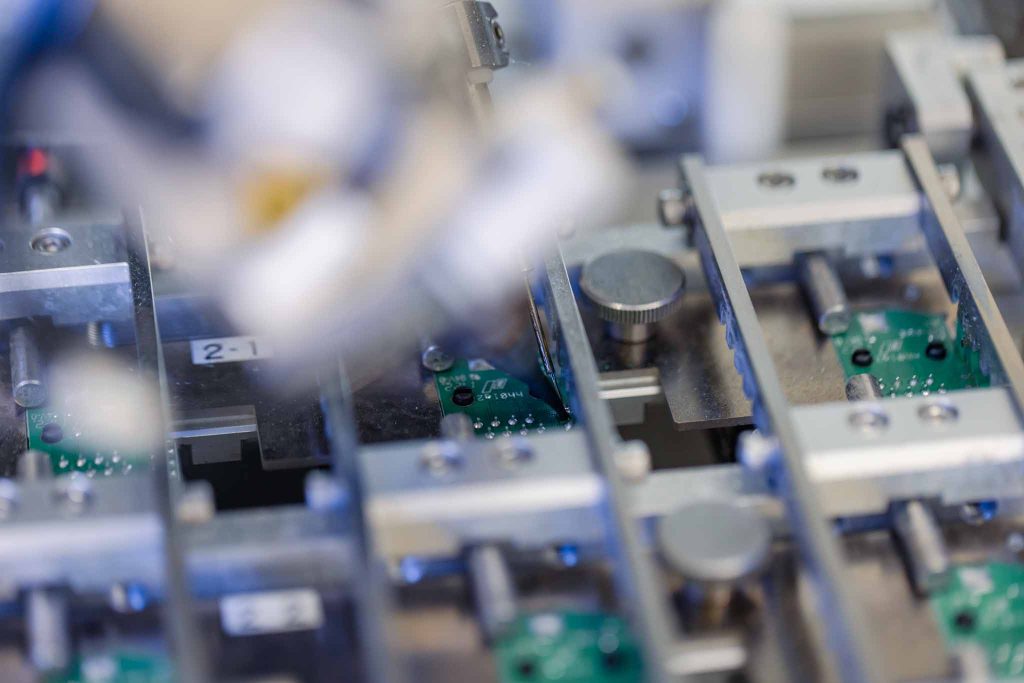

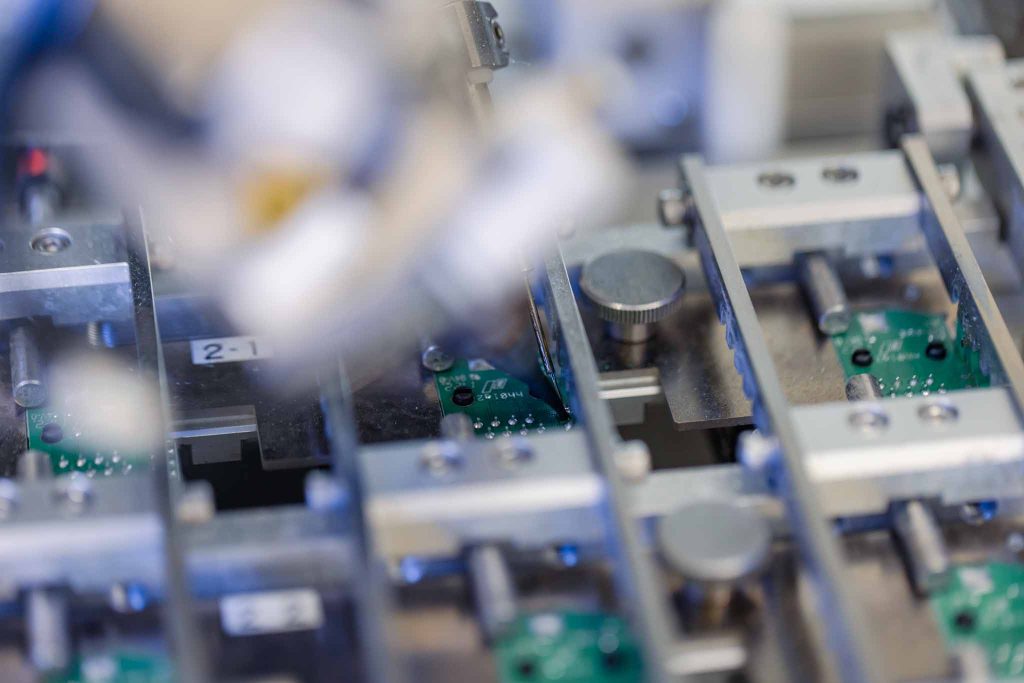

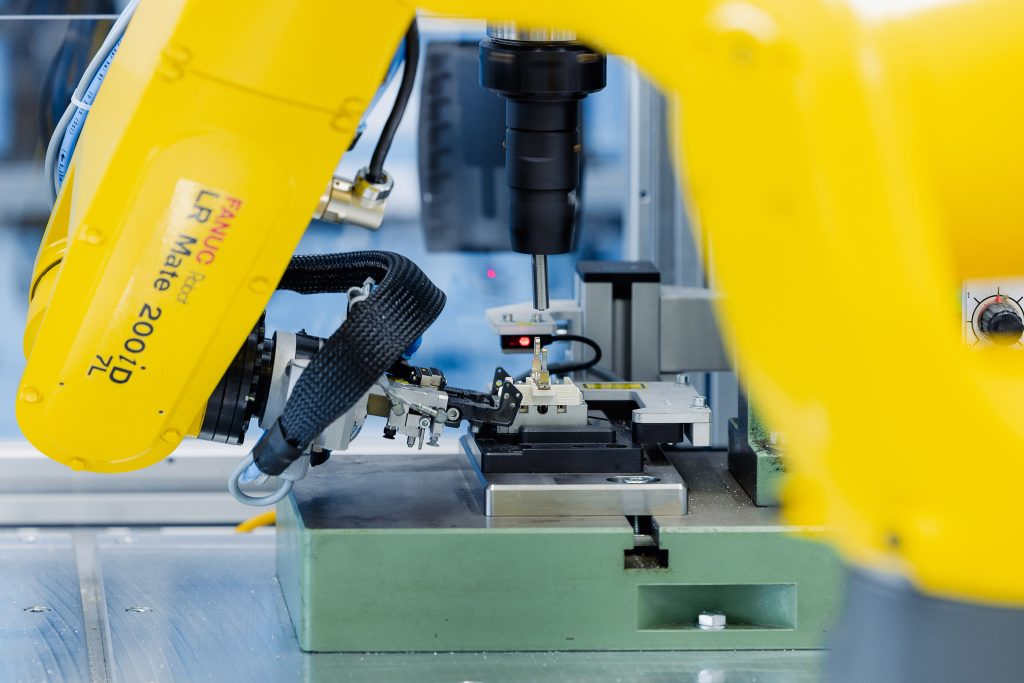

What we develop, we can also produce.

Our tested designs are industrialized in-house — with automated assembly, series validation and continuous quality monitoring.

Whether 100 or 50 000 unitsEvery production step is documented, tested and standard-compliant.

This creates Planning security and trustespecially for demanding partners who value control, precision and stability.

The smart home market doesn’t wait

SPECIALIZATION

Touch controls: High-quality control panels with plastic overmolding for smart home controls

Sensor housings: Precision-manufactured housings for temperature, motion and environmental sensors

Smart Home assemblies: Electromechanical components with integrated electronics for home automation

QUALITY STANDARDS

Start-up to market leader: Proven scaling expertise from small series to mass production

Scalable production: Flexible batch sizes from 100 to 50,000 units without capital investment

Parallel development: 50% Shorter development time thanks to simultaneous hardware and software development

MANUFACTURING EXPERTISE

Hybrid manufacturing: CNC machining, punching and plastic overmolding under one roof

Electronics integration: Component assembly with functional testing for smart home systems

Flexible series production: From prototype to large series with scalable batch sizes

Why is KOMOS the right partner?

KOMOS connects Entwicklungskompetenz, Fertigungstiefe und zertifiziertes Qualitätsmanagement. We do not see ourselves as a supplier, but as a partner at eye level — with responsibility for function, deadline and quality. Your advantages at a glance:

- Certified development and production according to ISO 9001 and ISO 13485 — auditable and reproducible

- Scalable production from 100 to 50,000 units — without additional capital commitment

- Cybersecurity by design — Secure boot processes, encrypted firmware and validated software updates

- Sustainable production through resource-efficient processes and modular architecture

Example from practice:

For a manufacturer of networked modules, KOMOS has realized a series production of 500 prototypes to 35,000 units per year scaled -

without additional tool costs.

Thanks to modular tool systems and flexible assembly islands, production could be gradually expanded without compromising on quality.

The result: stable process quality with constant testing effort.

How do we ensure measurable quality?

Every assembly undergoes documented test reports, series validation and traceable production processes — from the material to the end product.

All results are archived and are available digitally on request.

Schneller zur Marktreife

Durch strukturierte Entwicklung, integrierte Prozesse und kurze Entscheidungswege verkürzen wir Entwicklungs- und Industrialisierungszeiten messbar – besonders bei komplexen Smart-Home-Systemen.

- Are long development times slowing you down?

- Are high scaling investments putting a strain on your budget?

- Complex integration overwhelms your team?

What our customers say:

Frequently asked questions

What protection classes do your enclosures achieve?

Standard IP54, on request up to IP67 for underwater applications. Special sealing concepts ensure permanent tightness.

Can you manufacture vibration-resistant constructions?

Through FEM simulation and corresponding rib reinforcements We develop enclosures that can withstand extreme vibration stresses. withstand.

How quickly can you deliver prototypes?

Thanks to our four production technologies under one roof, we deliver we produce the first prototypes after just 2–3 weeks.

What surface treatments do you offer?

Powder coating, anodizing, galvanic coatings as well as special anti-corrosion treatments depending on the area of application.

How does the KOMOS app support IoT products?

Our KOMOS app automatically documents all software flashings, calibrations

and functional tests. Ideal for IoT certifications and field update management. and documentation considerably.

Which wireless standards can you implement in enclosures?

We develop housings for ZigBee, Z‑Wave, Bluetooth LE, WLAN, Thread and Matter — EMC-compliant with optimized antenna placement.

How do you ensure EMC conformity?

With shielding plates, EMC-compliant cable routing and tested materials — including preliminary EMC tests and validation.

How do you document quality and processes?

All process data is recorded digitally, stored in a traceable manner and made available in the customer portal.