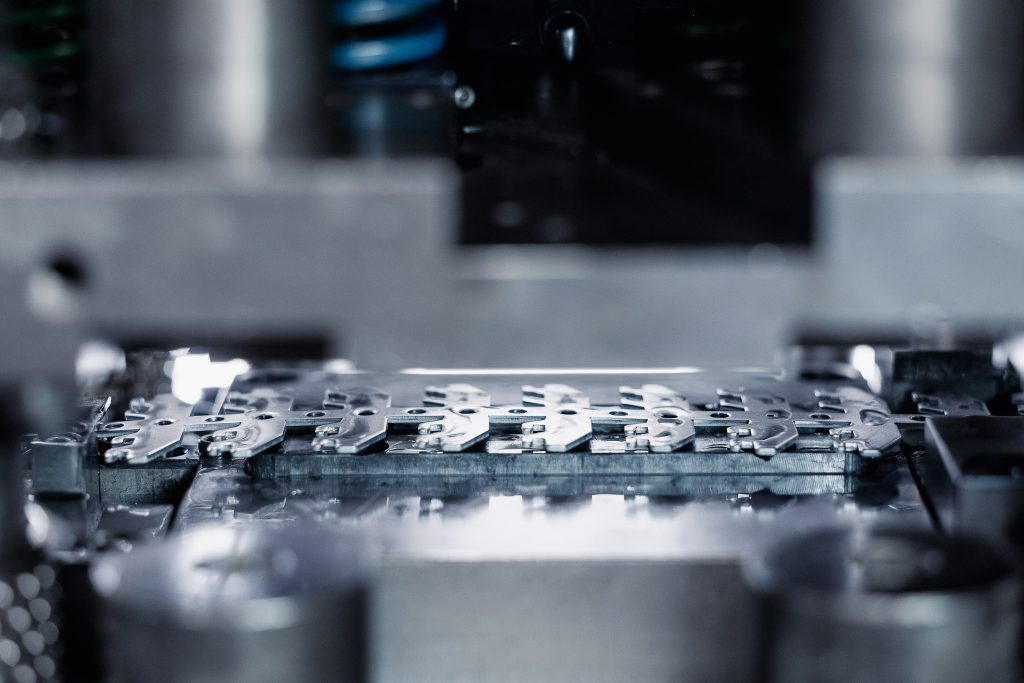

Qualität, die Ihre Serie absichert.

Mit unserer Mehrfachzertifizierung – ISO 9001 / ISO 13485 / VDE geprüfte Fertigungsstätte – verwandeln Qualitätsanforderungen in messbare, reproduzierbare Ergebnisse – von der Entwicklung bis zur Serie.

Certified quality —

100% Made in Germany

100% Made in Germany

Systematic quality assurance

Certified quality you can rely on

Unsere Prozesse sind zertifiziert – und im Alltag gelebt.

- ISO 13485: Lückenlose Rückverfolgbarkeit für sicherheitskritische Produkte

- ISO 9001: Systematische Verbesserung statt reaktiver Korrekturen

- VDE-certified production facility: Electrical safety to the highest standards

Qualität in Echtzeit – volle Transparenz

Mit der KOMOS App sehen Sie jederzeit, was in Ihrer Fertigung passiert – und warum.

- Lückenlose Rückverfolgbarkeit: Jedes Teil digital erfasst – von Charge bis Endprodukt.

- Intelligente Werkzeugüberwachung: Wartungsbedarf erkennen, bevor Ausfälle entstehen

- Digitale Produktakte: Alle Daten sofort verfügbar – messbar und nachvollziehbar

Fehler früh erkennen statt teuer beheben.

Unsere Systeme erkennen Abweichungen frühzeitig – bevor Ausschuss entsteht.

- Produktionsdaten werden kontinuierlich ausgewertet

- Präventive Qualitätskontrolle statt reaktiver Fehlerbehebung

- Bis zu 95 % weniger Reklamationen durch Früherkennung

Industry-specific quality standards

Meet medical technology standards — Comply with international safety standards

- ISO 13485 zertifizierte Plattform – verkürzt Ihre Zulassungszeit

- MDR-konforme Dokumentation von Anfang an – ohne Nacharbeit

- Klare Qualitätssignale statt Interpretationsspielraum

Guaranteeing automotive quality — error-free series processes and long-term stable product quality

- Bis zu 30% geringere Prüfkosten durch intelligente Qualitätssysteme

- 99,8% Erstmustergabe – OEM-erprobt

- <3 ppm über 5 Jahre – stabile Serienqualität

Recognizing quality risks at an early stage — Intelligent early quality detection prevents market failures

- KI erkennt Abweichungen in Produktionsdaten frühzeitig

- Prozesse passen sich automatisch an – bevor Fehler entstehen

- Bis zu 95% weniger Reklamationen durch präventive Qualitätssicherung

Qualität ist nichts ohne Verlässlichkeit.

Long-standing, cooperative customer relationships are based on trust. Our quality systems simultaneously meet the highest industrial and medical technology standards — a rare multiple competence on the market.