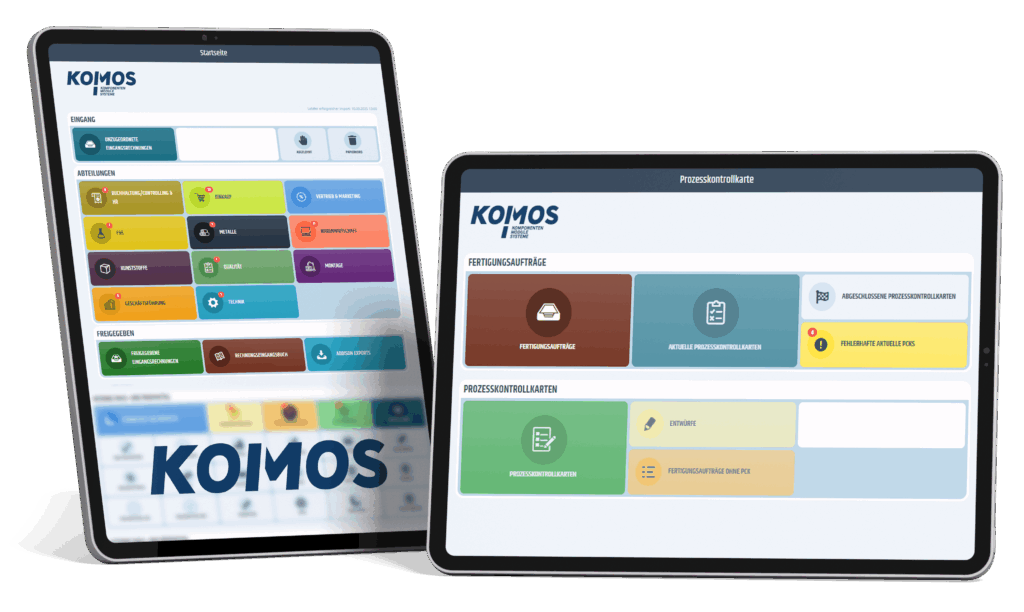

KOMOS-App – Digitale Prozessstrukturen für stabile Qualität.

Die KOMOS-App bildet die digitale Struktur unserer Produktion. Sie sichert Verantwortung über den gesamten Produktions- und Qualitätslebenszyklus – durchgängig und reproduzierbar.

Sie verbindet Fertigung, Qualität, Logistik und Infrastruktur in einer durchgängigen Prozessstruktur – vom Wareneingang bis zur Auslieferung.

Qualität entsteht nicht durch Kontrolle, sondern durch konsequent geführte Prozesse.

For you this means:

- Durchgängige Transparenz

- Hohe Prozessstabilität

- Documented quality in every project

Warum eine eigene digitale Struktur?

Komplexe Baugruppen, regulatorische Anforderungen und hohe Qualitätsansprüche lassen sich nicht mit isolierten Tools beherrschen. Deshalb haben wir eine eigene digitale Prozessstruktur entwickelt. Die KOMOS-App stellt sicher, dass Informationen, Freigaben und Entscheidungen dort zusammenlaufen, wo sie wirksam werden.

Das Ergebnis sind reproduzierbare Abläufe, belastbare Daten und eine Produktion, die auch unter Veränderung strukturell stabil bleibt.

Digitization that benefits you

Invoice

entry book

Das digitale Rechnungseingangsbuch stellt sicher, dass kaufmännische Prozesse nahtlos in die Produktions- und Qualitätsstruktur eingebunden sind – nachvollziehbar, prüfbar und revisionssicher.

- Automatisierte Abläufe sichern konsistente Freigabeprozesse

- Lückenlose Nachvollziehbarkeit unterstützt regulatorische Anforderungen

- Klare Prozessführung reduziert Abstimmungsaufwand

Delivery bill and goods flow management

All tools are continuously monitored, documented and maintained. This ensures that every product is manufactured using optimum production equipment — and that you can rely on consistent quality.

- Transparente Materialflüsse stabilisieren die Produktion

- Jede Bewegung bleibt dokumentiert und nachvollziehbar

- Regular maintenance ensures consistent product quality

Sampling and approval tool

Das Bemusterungs- und Freigabe-Tool verbindet technische Bewertung, Dokumentation und Entscheidung in einem durchgängigen Prozess – für sichere Serienfreigaben ohne Medienbrüche.

- Strukturierte Freigabeprozesse sichern belastbare Serienentscheidungen

- Documented approvals offer maximum traceability

- Transparent processes strengthen cooperation and trust

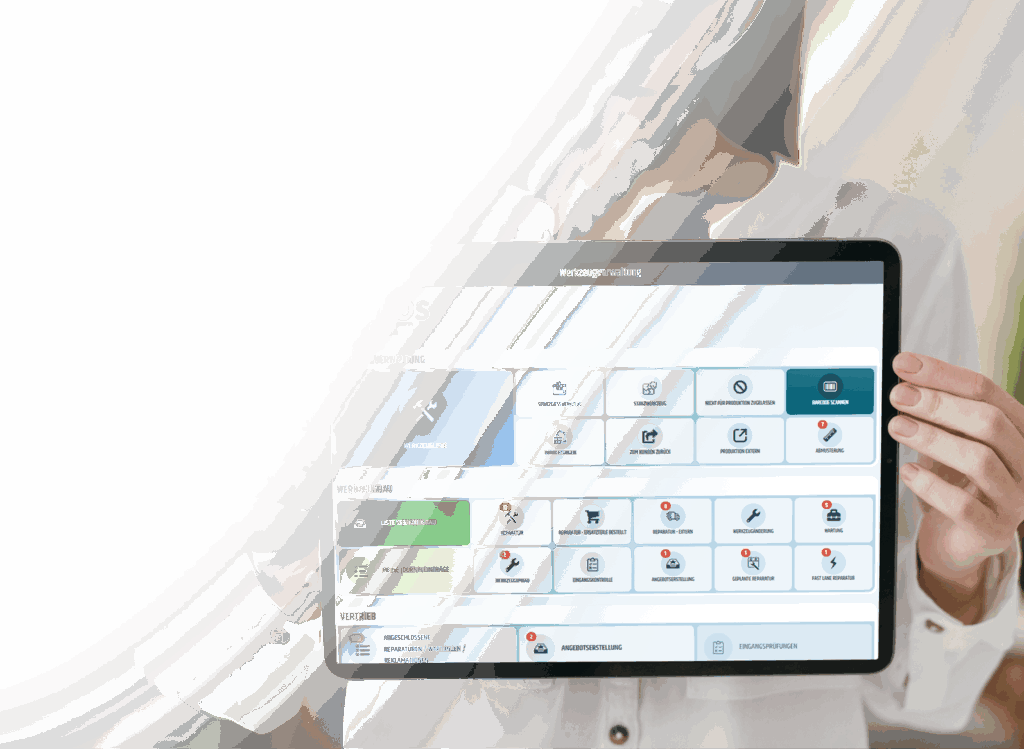

Tool lifecycle management

Thanks to continuously monitored tools, we ensure consistent quality for every production batch and avoid unplanned downtime. Your production remains reliable, plannable and efficient

- Regular maintenance prevents breakdowns

- Consistent quality over the entire product life cycle

- Complete tool history strengthens process reliability

Production area dashboards

Real-time data enables us to react to changes at an early stage, control processes in a targeted manner and minimize risks — even before they have an impact on quality or delivery dates.

- Early warning systems increase process stability

- Transparente Kennzahlen ermöglichen fundierte Entscheidungen

- Data-based control improves adherence to delivery dates

Digital

Process control card

Any deviation from the defined quality standard is immediately identified and rectified. This enables us to ensure consistent product quality and meet even the most demanding standard requirements.

- Early deviation detection prevents rejects

- Klar geführte Prozesse sichern reproduzierbare Ergebnisse

- Seamless documentation supports certifications

Measuring and test equipment management

Calibrations, maintenance and tests are automatically monitored and documented. This ensures maximum measurement accuracy and simplifies audit and certification processes.

- Reliable, reproducible measurement results

- Complete test and calibration history

- Simplified preparation for audits

Infrastructure and asset management

System statuses and maintenance cycles are monitored centrally and reported automatically. This ensures stable production processes and reliable delivery performance.

- Early detection of maintenance requirements

- Gesicherte Anlagenverfügbarkeit und stabile Prozesse

- Reliable production without unplanned downtime

Precise production — digitally controlled. That is KOMOS.

Über 30 Jahre Fertigungserfahrung treffen bei KOMOS auf modernste Digitalisierung. Dabei verstehen wir Technologie nicht als Selbstzweck, sondern als Struktur zur Absicherung unserer Prozesse. Mit der KOMOS-App haben wir eine interne Lösung geschaffen, die alle relevanten Informationen zentral zusammenführt, Prozesse sichtbar, steuerbar und effizient macht – und damit die Basis für Präzision, Termintreue und maximale Prozesssicherheit bildet.

Frequently asked questions

What data is stored and how long does it remain available?

Only process and project-relevant data such as order status, production progress, test values or energy indicators are recorded. Data is stored for as long as is necessary for order fulfillment, legal obligations to provide evidence or agreed retention periods.

For you this means All data is traceable, archived in a legally compliant manner and can be retrieved at any time if required.

How up-to-date is the data displayed in the app?

All relevant process information is recorded and synchronized in real time. Changes in order status, inspections or material movements are immediately visible in the system.

For you this means Based on current live data, we can make well-founded decisions at any time, control processes in a targeted manner and react to changes at an early stage — so that your project is implemented reliably, predictably and without delays.

Who has access to my project-relevant information?

Access is clearly regulated and role-based. Only authorized employees who are directly involved in your project can access relevant data — so your information remains protected and confidential at all times.

What happens in the event of system malfunctions or failures?

Our systems are monitored around the clock and have multi-level backup mechanisms. Even in the rare event of a malfunction, data is retained and processes can be continued within a very short time — without affecting delivery deadlines or product quality.

Can inspectors or auditors gain access to relevant information?

Yes — if required, we can provide audited, exported certificates from our system. These are fully documented and meet all requirements for audit and certification processes.

How do I benefit as a customer even though I don’t have access to the app myself?

The KOMOS app is an internal tool for controlling, documenting and optimizing all production and administrative processes. This means you benefit directly: processes are more efficient, decisions are more informed, evidence is fully documented and delivery dates can be planned more reliably — without any additional effort on your part.

Ist die KOMOS-App für Kunden zugänglich?

Die KOMOS-App ist ein internes System zur Steuerung unserer Produktions- und Qualitätsprozesse. Relevante Informationen stellen wir unseren Kunden strukturiert und projektspezifisch zur Verfügung.