Where technology meets trust.

We have been developing, manufacturing and assembling customized mechanical and electronic solutions for over 30 years. From the idea to series production — precise, reliable and tailored exactly to your needs.

Verantwortung aus Überzeugung.

Seit zwei Generationen.

Seit über drei Jahrzehnten steht KOMOS für Kontinuität und Verlässlichkeit.

Als Familienunternehmen in zweiter Generation übernehmen wir Verantwortung persönlich – gegenüber Kunden, Mitarbeitenden und Partnern.

-

Reliability & continuity:

Wir denken in langfristigen Partnerschaften – stabil, vorausschauend und verbindlich. -

Short decision-making processes:

Entscheidungen werden dort getroffen, wo Verantwortung getragen wird – direkt, schnell und praxisnah. -

Innovative strength with a human touch:

Technologie folgt bei uns dem Nutzen – Ihre Anforderungen stehen im Mittelpunkt jeder Entscheidung.

„Verantwortung zu übernehmen heißt für uns, die Herausforderungen unserer Kunden ernst zu nehmen. Wir liefern das Teil, das das Bild komplett macht.“

Antje Blumentritt, Geschäftsführende Gesellschafterin KOMOS GmbH

Familiengeführt. Verantwortung als Prinzip.

Seit über 30 Jahren steht KOMOS für präzise gefertigte Baugruppen und verlässliche Systemlösungen.

Als familiengeführtes Unternehmen handeln wir persönlich – von der Entwicklung bis zur Serie.

Technologies with a systems approach

Kunststoff-Spritzguss, Drehteile und Stanztechnik werden zu leistungsfähigen Hybridlösungen kombiniert.

Montagefertig vorbereitet, geprüft und exakt auf Ihre Anforderungen abgestimmt.

From the idea to series production

Projekte werden ganzheitlich begleitet – von der technischen Lösung bis zur Serienreife.

Funktion, Wirtschaftlichkeit und Qualität stehen dabei im Mittelpunkt.

Certified safety — in every industry

In regulierten und sicherheitskritischen Anwendungen zählen stabile Prozesse und nachvollziehbare Abläufe.

Zertifizierungen nach DIN EN ISO 9001, ISO 13485 sowie IATF 16949 sichern Qualität, Flexibilität und Effizienz.

Produktfreigaben erfolgen nach VDA oder PPAP – belastbar und transparent.

Industry experience that creates trust

Unsere Baugruppen kommen in Medizintechnik, Automotive, Elektrotechnik, Maschinenbau sowie Luft- und Raumfahrt zum Einsatz.

Jedes Teil, das KOMOS verlässt, steht für höchste Verantwortung – technisch, wirtschaftlich und menschlich.

KOMOS: Innovation — Diversity — Future

In einem zunehmend komplexen Umfeld zählen technologische Weiterentwicklung, flexible Prozesse und verlässliche Strukturen. Gezielte Investitionen in Technologien, Digitalisierung und Fertigungskapazitäten schaffen Lösungen mit langfristiger Sicherheit und Anpassungsfähigkeit.

Zukunftssicherung bedeutet dabei, verantwortungsbewusst und partnerschaftlich zu handeln – gegenüber Kunden, Mitarbeitenden und Ressourcen.

Sockets & connection modules

Modulare Anschlusslösungen müssen sicher, langlebig und montagefreundlich sein.

Ob medizinische Steckdosenleisten oder Module für LAN, Telefon und TV – robuste Systeme sorgen für zuverlässige Funktion im Einsatz. Exakt abgestimmt auf die jeweilige Anwendung.

Reliability. Proximity. Made in Germany.

Kurze Wege, direkte Kommunikation und schnelle Entscheidungen prägen die Zusammenarbeit im Alltag. Regionale Fertigung in Deutschland sichert Qualität, Termintreue und schnelle Reaktionszeiten. Ein Vorteil, der im Tagesgeschäft den Unterschied macht.

Komplexe Systeme

Individuelle Aufgaben erfordern technisches Know-how, vernetzte Prozesse und Erfahrung.

So entstehen passgenaue Lösungen – von der ersten Idee bis zur Serienreife. Auch dann, wenn Anforderungen vom Standard abweichen.

Future through further development

Zukunftsfähigkeit entsteht durch kontinuierliche Weiterentwicklung.

Forschung, Digitalisierung und flexible Fertigungskapazitäten schaffen die notwendige Agilität. Für Lösungen, die auch morgen bestehen.

KOMOS: Verlässlichkeit in komplexen Projekten

Seit über 30 Jahren ist die KOMOS GmbH aus Bürgel Partner für anspruchsvolle Auftragsfertigung. Unternehmen verschiedenster Branchen verlassen sich auf unsere Erfahrung, technische Kompetenz und die Fähigkeit, auch komplexe Anforderungen sicher umzusetzen.

KOMOS denkt in Lösungen, handelt verantwortungsvoll und bleibt konsequent kundenorientiert.

Regional verwurzelt, national im Einsatz.

2025 — Everything comes together

With the new infrastructure tool, we have consistently linked our digital applications with one another.

Equally important is the project to link the sampling, dashboards and process control card, which are now merging into one integrated system — for greater efficiency, transparency and safety.

2024 — Abolition of internal e‑mails

As part of our digitalization strategy, we implemented a further systematic step in 2024: Internal e‑mails have been completely abolished.

Instead, we use a new Module in our ERP system, the information on a ZDF basis (figures, data, facts) centrally.

This means that our production issues are clearly documented, processed more quickly and can be tracked transparently for everyone involved.

The result: less communication effort, more efficiency — and a consistent focus on digital, fact-based processes.

2024 — From sampling to the dashboard — everything at a glance

With the new Sampling tool approvals can be carried out much faster, in a more structured and traceable manner. Customers benefit from clear documentation and our teams benefit from transparent processes.

At the same time, the first Dashboards that show key figures such as quality, capacity utilization and project status in real time. This allows us to create a new level of transparency and process reliability — both internally and for our customers.

2023 — Making digitalization & process optimization visible

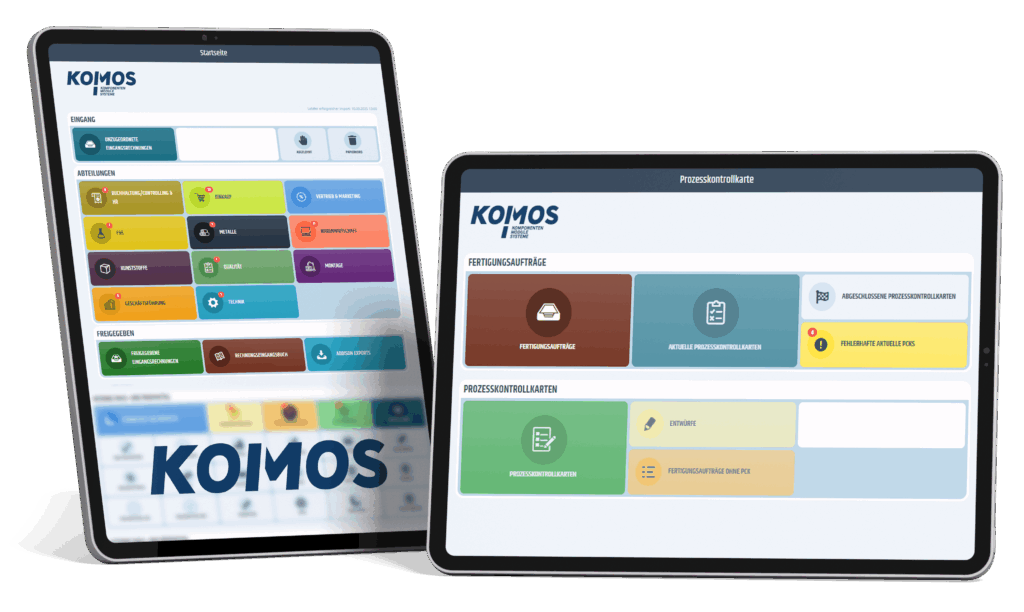

With the KOMOS app, we have digitized our processes and made them more transparent. Customers benefit from real-time information, clear traceability and an integrated digital process control cardthat makes quality data visible at all times. This provides employees with a tool for efficient workflows and structured process reliability.

2022 — Digitization, next step

Digitalization continues: Tooling and measuring and testing equipment tools are paving the way for the future, as is the new energy management system — measures that are proving to be optimal every day, including for KOMOS customers.

2022 — new working environment

The administration building was renovated and now has two open-plan offices and a staff kitchen. This working environment promotes internal communication and strengthens the working atmosphere, creativity and efficiency.

2021 — KOMOS goes digital

KOMOS launched its digitalization offensive together with a comprehensive machine investment programme. This included the introduction of a control station and an invoice processing tool.

2020 — Generation change II

The generational change that began in 2004 was completed at the start of 2020: Founder Manfred Schneider transferred his shares to Antje Blumentritt; since March 1, 2020, KOMOS GmbH in Bürgel has been represented by Antje Blumentritt and Karsten Blumentritt as managing directors.

2016 — Future

Sustainability has been an important corporate value from the very beginning. This is why KOMOS in Bürgel implemented an energy management system in 2016 and put its first photovoltaic system into operation in 2019.

2010 — more capacity II

In 2010, a new two-storey injection molding and storage hall was put into operation in Bürgel, and the former injection molding hall was converted into an assembly department with the latest assembly machines. This expansion of production capacity also included investments in new packaging machines with printing and fully automatic assembly machines.

2004 — R&D

An independent R&D team was also set up in 2004. This enabled the first customer orders to be implemented as complete solutions from development to assembly. At the same time, KOMOS in Bürgel developed the data and network technology product family and various products for applications in medical and electrical engineering.

2004 — Generation change I

Constanze Bürger and Karsten Blumentritt expanded the management team; KOMOS founder Manfred Schneider transferred the first shares in the company to his daughters Constanze Bürger and Antje Blumentritt — important steps for the continuation of the Bürgel-based family business. Manfred Schneider retired from the management in 2006.

1999 — Connection under this module

Something of our own: The opportunity to take over the production and marketing of the Busch Jaeger appliance box was the starting signal for the development of KOMOS’ own product range of connection modules in 1999. This was followed in 2001 by 4- and 6‑way socket strips, which have been further developed into medical socket strips to this day; in 2010, the modular connection unit in the Cat. 6A category from Bürgel was launched on the market.

1997 — more capacity I

The first new production hall with a new external warehouse went into operation in Bürgel in 1997. Since its foundation, the customer and technology base has been significantly expanded, with highlights such as banjo bolts from the turning shop, window regulator buttons and brake systems for the automotive industry or energy cubes for production plants. During this time, the basis for today’s KOMOS range of connection components was created.

1993/94 — Windows and alarm

After expanding the production spectrum to include its own window construction, the first product developed by KOMOS itself was established on the market in 1994: the modular alarm transmitter system.

1991 — Start

Even then, products and assemblies made of plastic and metal were manufactured for the electrical and communications industry: On October 1, 1991, Manfred Schneider founded KOMOS GmbH by acquiring the “Armaturen Bürgel” division of Tridelta AG with the “stamping and bar turning” and “plastic injection molding with assembly” departments and almost 100 employees.

2025 — Everything comes together

With the new infrastructure tool, we have consistently linked our digital applications with one another.

Equally important is the project to link the sampling, dashboards and process control card, which are now merging into one integrated system — for greater efficiency, transparency and safety.

2024 — Abolition of internal e‑mails

As part of our digitalization strategy, we implemented a further systematic step in 2024: Internal e‑mails have been completely abolished.

Instead, we use a new Module in our ERP system, the information on a ZDF basis (figures, data, facts) centrally.

This means that our production issues are clearly documented, processed more quickly and can be tracked transparently for everyone involved.

The result: less communication effort, more efficiency — and a consistent focus on digital, fact-based processes.

2024 — From sampling to the dashboard — everything at a glance

With the new Sampling tool approvals can be carried out much faster, in a more structured and traceable manner. Customers benefit from clear documentation and our teams benefit from transparent processes.

At the same time, the first Dashboards that show key figures such as quality, capacity utilization and project status in real time. This allows us to create a new level of transparency and process reliability — both internally and for our customers.

2023 — Making digitalization & process optimization visible

With the KOMOS app, we have digitized our processes and made them more transparent. Customers benefit from real-time information, clear traceability and an integrated digital process control cardthat makes quality data visible at all times. This provides employees with a tool for efficient workflows and structured process reliability.

2022 — Digitization, next step

Digitalization continues: Tooling and measuring and testing equipment tools are paving the way for the future, as is the new energy management system — measures that are proving to be optimal every day, including for KOMOS customers.

2022 — new working environment

The administration building was renovated and now has two open-plan offices and a staff kitchen. This working environment promotes internal communication and strengthens the working atmosphere, creativity and efficiency.

2021 — KOMOS goes digital

KOMOS launched its digitalization offensive together with a comprehensive machine investment programme. This included the introduction of a control station and an invoice processing tool.

2020 — Generation change II

The generational change that began in 2004 was completed at the start of 2020: Founder Manfred Schneider transferred his shares to Antje Blumentritt; since March 1, 2020, KOMOS GmbH in Bürgel has been represented by Antje Blumentritt and Karsten Blumentritt as managing directors.

2016 — Future

Sustainability has been an important corporate value from the very beginning. This is why KOMOS in Bürgel implemented an energy management system in 2016 and put its first photovoltaic system into operation in 2019.

2010 — more capacity II

In 2010, a new two-storey injection molding and storage hall was put into operation in Bürgel, and the former injection molding hall was converted into an assembly department with the latest assembly machines. This expansion of production capacity also included investments in new packaging machines with printing and fully automatic assembly machines.

2004 — R&D

An independent R&D team was also set up in 2004. This enabled the first customer orders to be implemented as complete solutions from development to assembly. At the same time, KOMOS in Bürgel developed the data and network technology product family and various products for applications in medical and electrical engineering.

2004 — Generation change I

Constanze Bürger and Karsten Blumentritt expanded the management team; KOMOS founder Manfred Schneider transferred the first shares in the company to his daughters Constanze Bürger and Antje Blumentritt — important steps for the continuation of the Bürgel-based family business. Manfred Schneider retired from the management in 2006.

1999 — Connection under this module

Something of our own: The opportunity to take over the production and marketing of the Busch Jaeger appliance box was the starting signal for the development of KOMOS’ own product range of connection modules in 1999. This was followed in 2001 by 4- and 6‑way socket strips, which have been further developed into medical socket strips to this day; in 2010, the modular connection unit in the Cat. 6A category from Bürgel was launched on the market.

1997 — more capacity I

The first new production hall with a new external warehouse went into operation in Bürgel in 1997. Since its foundation, the customer and technology base has been significantly expanded, with highlights such as banjo bolts from the turning shop, window regulator buttons and brake systems for the automotive industry or energy cubes for production plants. During this time, the basis for today’s KOMOS range of connection components was created.

1993/94 — Windows and alarm

After expanding the production spectrum to include its own window construction, the first product developed by KOMOS itself was established on the market in 1994: the modular alarm transmitter system.

1991 — Start

Even then, products and assemblies made of plastic and metal were manufactured for the electrical and communications industry: On October 1, 1991, Manfred Schneider founded KOMOS GmbH by acquiring the “Armaturen Bürgel” division of Tridelta AG with the “stamping and bar turning” and “plastic injection molding with assembly” departments and almost 100 employees.